模具設計

模具設計:UG設計軟體 / Solidwork設記軟體 / Pro/e設計軟體

模具設計:UG設計軟體 / Solidwork設記軟體 / Pro/e設計軟體

車床1台

銑床5台

模床2台

模具檢測

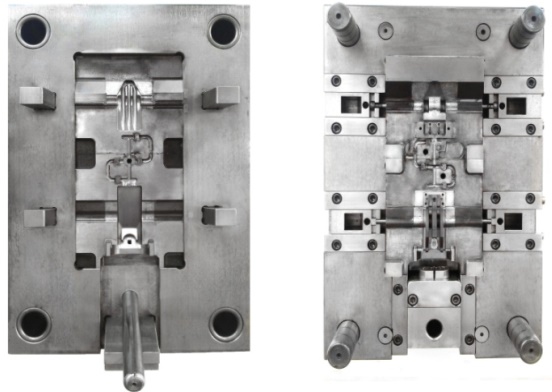

模具設計與製作

(1)特色

1.模具圖面化: 可減少模具設計過程之錯誤,並迅速呈現與變化產品的造型和功能需求。

2.模具標準化: 標準化的規格提供,讓廠商方便維修及變更。

3.模具生產自動化: 可以減低生產成本及人員之調配並縮短生產的週期。

4.產品品質化: 品質嚴格的控制可減少試模次數、成本及風險,確保產品品質及上市時機。

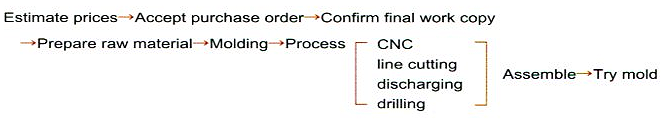

(2)模具製作流程

Mold Design and Making

I. Features:

1. Diagrams for molding: Reduces any error or blunder committed during mold design, easily and rapidly present and modify product designs and functions required.

2. Mold standardization: Provides clients with standardized specs for further alteration and maintenance.

3. Mold making automation: Lowers production cost, shortens lead time and smoothes personnel dispatch.

4. Product quality: Strict QC may reduce times for mold trial, cost and risk, assure product quality and the timing for markets.

II. Mold making process: